Specializing in the production of vacuum, semiconductor, and rubber industries

Armored heaters, thermocouples, thermal resistors, precision machined parts, sheet metal parts and other series of products

Service Hotline

86-21-3769128286-15372369261

CLASSIFICATION

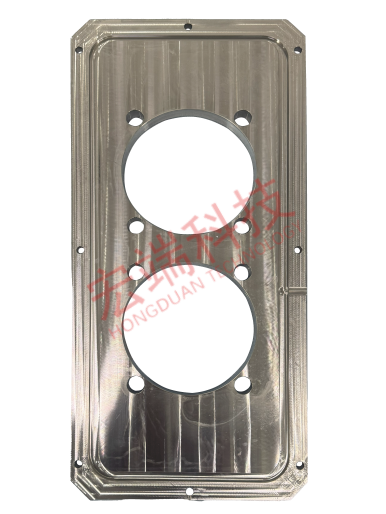

[Category]Precision workpiece series

Stainless steel chamber is a sealed container used to maintain high or low vacuum environments, usually made of stainless steel, widely used in scientific research, industrial production, and precision equipment.

Product Introduction

Hongduan brand Stainless steel chambers are widely used in high or low vacuum environments due to their excellent sealing, corrosion resistance, mechanical strength, and thermal stability.

Specifications&Materials

Customized

SUS304

Usage&Features

The following are typical application scenarios and examples:

1. Semiconductor industry

Chip manufacturing (photolithography, etching, deposition)

In plasma etching machines or chemical vapor deposition (CVD) equipment, the stainless steel chamber maintains a low vacuum (10 ⁻³ -10 ⁻⁶ Pa) to ensure the purity of the process gas.

Ion implanter

The vacuum chamber prevents impurity contamination and ensures precise ion beam injection into the wafer.

2. Aerospace

Spacecraft simulation testing

Simulate a space ultra-high vacuum environment on the ground (such as 10 ⁻⁷ Pa) to test the performance of satellite or telescope components (such as the mirror calibration of the James Webb Telescope).

rocket propulsion system

The fuel storage tank and propellant pipeline are equipped with stainless steel vacuum chambers to prevent oxidation or leakage.

3. Medical and Biotechnology

Electron Microscopy (SEM/TEM)

The sample chamber requires high vacuum (10 ⁻⁴ -10 ⁻⁷ Pa) to avoid electron beam scattering, and the stainless steel chamber ensures imaging clarity.

Proton therapy (cancer radiotherapy)

The accelerator vacuum chamber ensures that there is no energy loss during the transmission of the proton beam.

4. New energy

Nuclear fusion devices (such as Tokamaks)

A vacuum chamber (such as ITER's stainless steel vacuum chamber) is used to confine high-temperature plasma, requiring a vacuum degree of 10 ⁻⁵ Pa or higher.

Lithium ion battery production

The drying and packaging process of electrode materials requires a low vacuum environment to prevent moisture and oxygen contamination.

6. Precision manufacturing

Thin film coating (optical, decorative coating)

In magnetron sputtering or vapor deposition equipment, the stainless steel chamber maintains a vacuum (10 ⁻² -10 ⁻⁵ Pa) to achieve uniform coating.

vacuum brazing

When welding precision components such as aircraft engine blades, vacuum prevents oxidation and enhances weld strength.

- Shanghai Hongduan Precision Machinery Co., Ltd

Address: Building 1, No. 208 Yefan Road, Yexie Town, Songjiang District, Shanghai

Telephone: 86-21-37691282, 37691283

Email: sales@hongduan.net

- Jiaxing Branch Factory

Address: No. 199 Qingliang Avenue, Yaozhuang Town, Jiashan County, Jiaxing City, Zhejiang Province

Telephone: 86-21-37691282. 37691283

Email: sales@hongduan.net

- Tokyo Office, Honglin Co., Ltd

Address: 21-3 Shin Orange 4-chome, Minato ku, Tokyo

Telephone: 03 6895 7452

Email: h_miyashita@honglin.jp; caij@honglin.jp; shixiaojing@honglin.jp